TECHNOLOGY

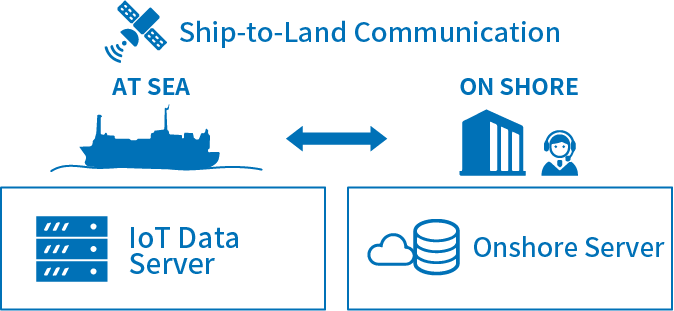

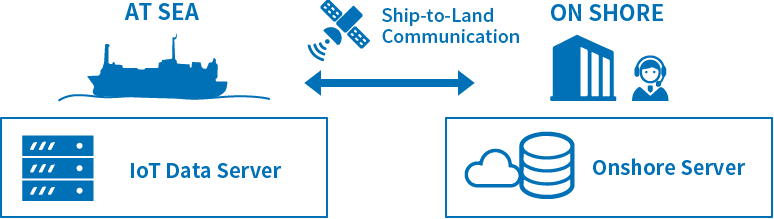

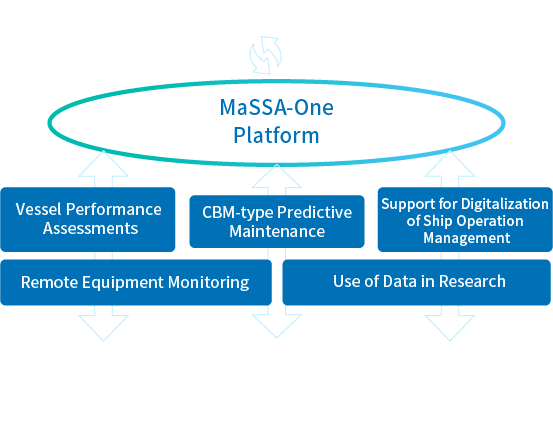

MaSSA-One collects and stores a wide array of data on the ship's engines, cargo handling, voyages and more, and shares the data with the onshore offices to provide ship voyage support applications.

Shipboard Crew Support Applications

We create shipboard application environments to support ship’s crew performance

- Equipment Monitoring

- Troubleshooting Support

- ・・・

- ・・・

- ・・・

- ・・・

Onshore Monitoring and Information Analysis Applications

Sophisticated data analysis and ship voyage support applications are provided for the onshore office

- Equipment Monitoring

- Data Download

- Maintenance Support

- Ship Voyage Support

- ・・・

- ・・・

Application Development and Service Provision

Marine Equipment Manufacturer

Application Development and Service Provision

Marine Equipment Manufacturer

AT SEA

Shipboard Crew Support Applications

We create shipboard application environments to support ship’s crew performance

- Equipment Monitoring

- Troubleshooting Support

- ・・・

- ・・・

- ・・・

- ・・・

ON SHORE

Onshore Monitoring and Information Analysis Applications

Sophisticated data analysis and ship voyage support applications are provided for the onshore office

- Equipment Monitoring

- Data Download

- Maintenance Support

- Ship Voyage Support

- ・・・

- ・・・

User

User

User- Shipowner (Ship Management Company)

- Operator

- Shipbuilding Yard

- Marine Equipment Manufacturer

- ・・・

Application Development and Service Provision

Marine Equipment Manufacturer

Application Development and Service Provision

Marine Equipment Manufacturer

01.Real-time visual display of ship-related data and provision of crew support applications.

● Various ship-related data collected via the IoT Data Server can be confirmed in real time from onboard the ship.

IoT Data Server Features

– Complies with ISO 19847/19848 international standards for shipboard data servers

– Converts ship-related data to ISO 19848–compatible formats and stores it (formats: CSV, Modbus, IEC 61162-1/61162-2)

– Saves ship-related data in one-second cycles and stores it for one month's time

– Can be configured by the user as required to send data to a MaSSA-One onshore server

● Installation of applications to support the ship's crew

MaSSA-One provides the applications that enables appropriate and speedy recovery response on board and supports efficient operation in the event of trouble.

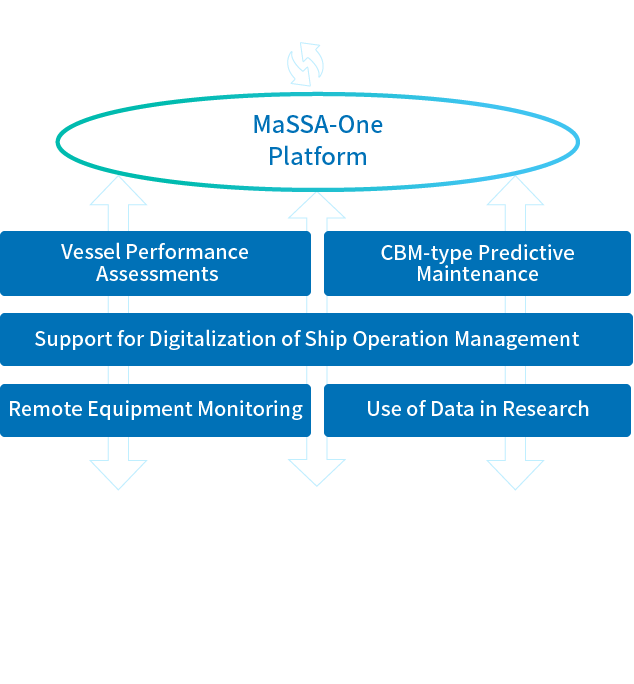

02.Sophisticated data analysis at the onshore office

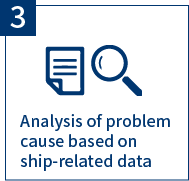

● Collected ship-related data is utilized in the development of applications for responding to problems and malfunctions, maintenance support, and more.

● Enables more advanced onshore analyses in response to problems in order to determine their causes.

● Facilitates optimized management of shipboard equipment by using condition-based maintenance (CBM) rather than time-based maintenance (TBM)

03.Flexible responses to a wide range of needs.

● Users can choose from a lineup of continually developed applications, selecting only those they wish to use.

● Applications from other companies as well as service collaborations (via ISO APIs) are also available.

● MaSSA-One onshore servers are capable of coordinating with other types of onshore servers.

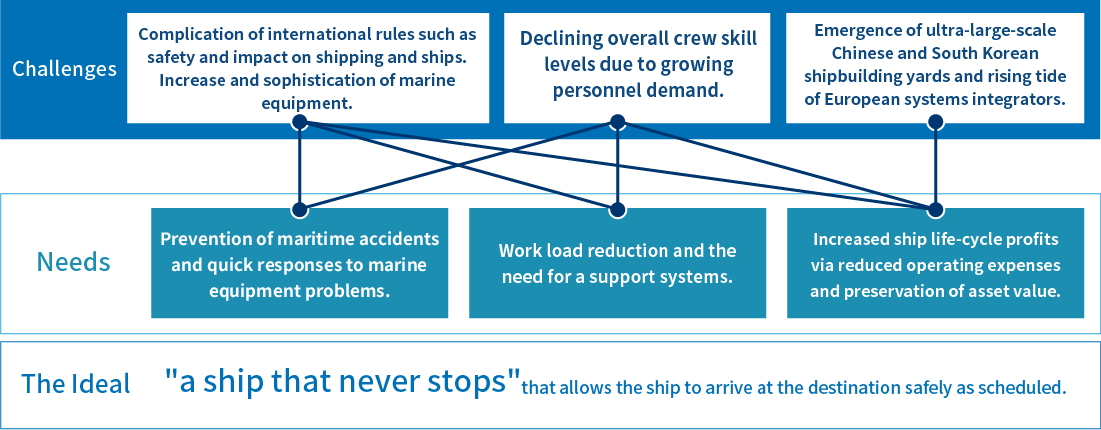

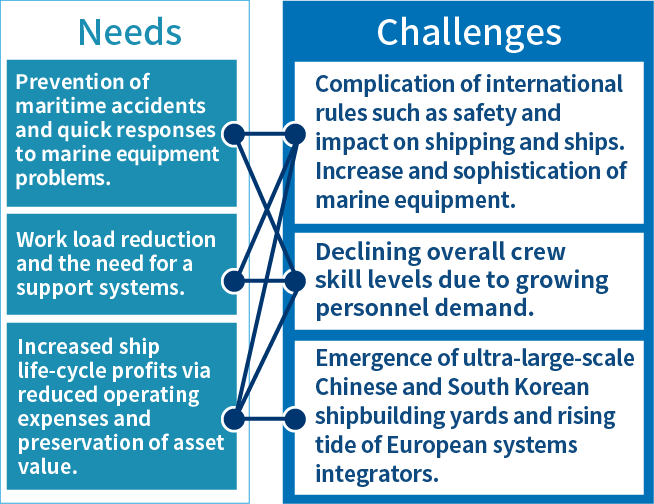

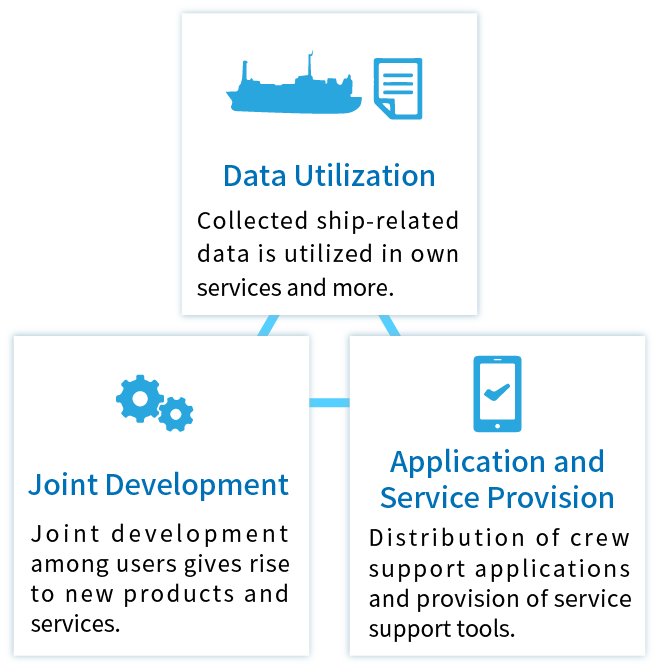

CONCEPT

We develop the MaSSA-One platform to share ship-related data and provide beneficial applications, thus fostering an ecosystem that benefits all participating users.

Uses in After-sales Service Operations (By Marine equipment Manufacturer)

- ●Collection of Ship-related data without high initial cost requirements.

- ●Data-based maintenance and repair (CBM) proposals.

- ●Detailed onshore analysis of causal factors in the event of a malfunction or breakdown.

Usage example

Analyses of ship-related data in response to problems, enabling quicker response times and reduced numbers of visits for repairs.

Application Development Example 1

"MaSSA Insight ~WADATSUMI~" is a data utilization application that monitors necessary items without hassle and does not overlook the buds of risk.

Engine Monitor

Engine Monitor

- ●Shipboard equipment monitoring

- Usable aboard the ship, and also at the onshore office to enable real-time monitoring of conditions inside the ship from land.

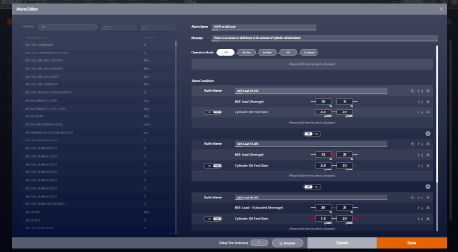

Knowledge Alarm

Knowledge Alarm

- ●Knowledge Alarm

- Unique alerts can be set up based on our experience and knowledge in ship management, and continual risk monitoring can be carried out for the ship.

Application Development Example 2

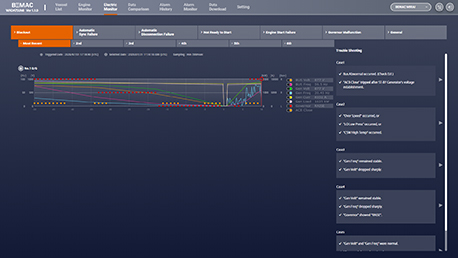

Electric Trouble-shooting (Application for analyzing generator malfunctions)

Blackout diagnostic screen

Blackout diagnostic screen

- ●Onbord analysis solution of defective

- An automatic diagnostic activates in response to power blackouts in order to determine probable causes and provide instructions for rapid restoration.

- ●Cause analyses by Marine equipment Manufacturers

- Equipment-related data from before and after the malfunction is saved on the IoT Data Server and sent to BEMAC and party involved, where sophisticated analyses are carried out onshore to pinpoint the cause of the problem.

NewsGo Back >

Catalog Download

Contact

Please use this contact form for any questions or comments you may have for us, or if you would like to contact us regarding participation as a partner company.